Installation Examples

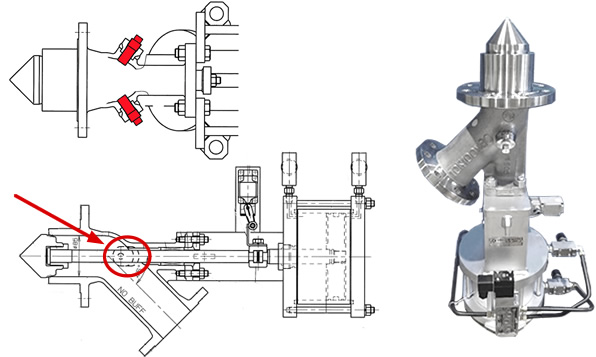

Case 1:

and Cleans the Interior

Needs

There is a need to break up the fluid adhering to the bottom of the tank.

In addition, fluid adheres to the inside of the valve and needs to be cleaned out, but removing the valve each time is a lot of work.

Solutions

Aska’s tapered valve disc breaks up material adhering to the bottom of the tank.

The inside of the valve was fitted with nozzles to enable places inside the valve where materials adhere to be cleaned without removing it.

Customer Feedback

We previously broke up the adhesions by punching them with the rod from the top of the tank. However, these materials are now removed automatically when opening and closing the valve, ensuring that the fluid discharges smoothly.

There is no need to remove the valve after each batch.

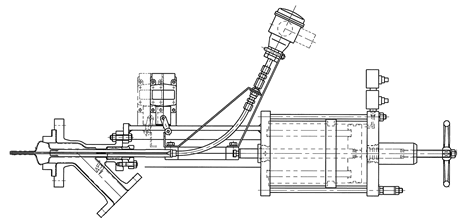

Case 2:

the Temperature inside the Tank

Needs

When discharging fluid from the tank, there is a need to measure the temperature continuously until there is no fluid left.

In order to periodically calibrate the thermometer, there is a need to be able to remove it without disassembling the valve.

Solutions

Aska suggested a flush bottom tank valve in which the thermometer can be inserted through the valve rod and the disc. The thermometer can now be removed even when the valve is still attached to the tank. There was no space below the cylinder to remove the thermometer, so Aska recommended a type in which the thermometer could be removed or attached from the side.

Customer Feedback

No longer any need to install a thermometer in tank.

Single unit does double duty as thermometer and ON-OFF valve.

Teflon® coating dispels concerns about valve corrosion by highly corrosive fluids.

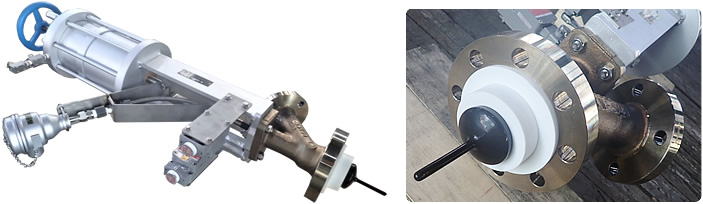

Case 3:

Needs

There is a need for an automatic valve with jacket that can be used while partially opened, and can adjust the flow rate.

Solutions

Aska recommended an angle control valve in which air is used for opening/closing. The correct flow rate can be set using a signal from a sensor.

Customer Feedback

Since the flow rate can now be controlled automatically instead of manually, there is no flow rate variance.

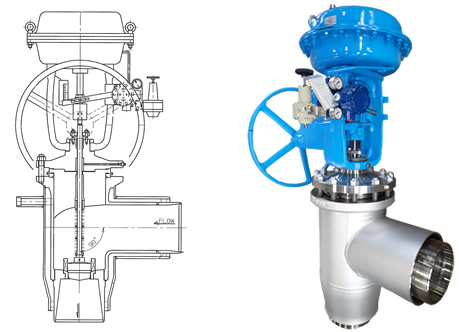

Case 4:

Needs

We want to extract polymer for film that does not meet the product specifications at the beginning of the flow. However, there is no suitable equipment because it is used under high temperature and high pressure conditions.

Solutions

Aska suggested a compact, dead space free lift plug valve with molded heater. The valve was equipped with a drain mechanism to discharge out-of-spec polymer just before the polymer flowed out as the final product.

Customer Feedback

It can be switched easily using the handle. Since only a single valve is needed for drain removal and switching, the installation space required can be minimized.